Take A Tour of The New Paradox Brewery in North Hudson

/By Anthony Batson

Paul Mrocka, the onetime home brewer who turned a hobby into a thriving business, has a broad smile on his face. Like a kid in a candy store.

But this store happens to be a metal and cement shell, on a large lot on Route 9 north of Schroon, where a brand new rental crane, a Bobcat and a dozen tradesmen are performing a well-rehearsed routine.

We are visiting the construction site of the new Paradox Brewery on the edge of the grounds of Frontier Town, the long shuttered western theme park in North Hudson.

Paul took me on a tour of what is sure to become a shrine to craft brewing in the Adirondacks, something that a few years ago was unimaginable. The ground was broken in April and if all goes well the tasting room will be open in the spring of 2019. Brewing may begin earlier.

“Can you believe the progress we are making?” asks Paul as we pull up.

Underfoot is soft, sandy soil, which has helped speed up construction. (Paul admits it was just a fluke that this particular parcel of land is not some classic Adirondack rock strewn chunk of turf).

A few days before the tour Paul was looking over the controls of a cockpit in the Gulfstream jet he was flying from Atlanta to Morristown, New Jersey.

For now, Paul’s full-time gig is senior captain for Honeywell, which manufactures many of the avionics on these $65 million plus jets.

Back on the ground, Paul and his dog Olive walk towards the building site. It’s late afternoon on a hot summer’s day. Paul checks in with Carl Carlson, his General Contractor and the owner of that new Bobcat.

Paul stops to chat with the supervisor of a crew of ironworkers from Vermont, busily bolting steel beams together for the building’s sides and roof.

I comment that it looks like a ski lodge.

“Yeah, it’s kind of modern industrial with a ski lodge look to it. It's not Adirondack tacky, but it's got a little bit of an Adirondack theme to it, you know, the colors, and the little bit of the wood,” Paul says. The brewery will feature some repurposed items from Frontier Town.

“The siding of the tasting room will be green and the sides are more of a slate color for the brewery”.

To get this far, Paul and his wife Joannie, the brewery’s other cofounder, have overcome numerous hurdles.

From figuring out where to build the new brewery, how to finance the $5.2 million project, detangling red tape to overcome the delays due to the (20 plus) permits, to dealing with the newly imposed US tariffs on steel imports (from Canada), those issues have produced more than a few sleepless nights.

But today Paul is looking to the future success of the venture and a potential payday for the brewery’s original investors.

Then there is that payday for the local economy: jobs created building the brewery, and in the months ahead, for workers who will be hired to work in the brewery.

And the economy of North Hudson and Schroon may also benefit with the arrival of new, modern hotels and inns. The future already looks good with the recent ribbon cutting of the Frontier Town Equestrian, camping and day use area.

There are also those of us who will help make all of the above a reality: Thirsty consumers and lovers of craft beer in the large tristate area, Once at full production, the brewery will expand its offerings all over the US.

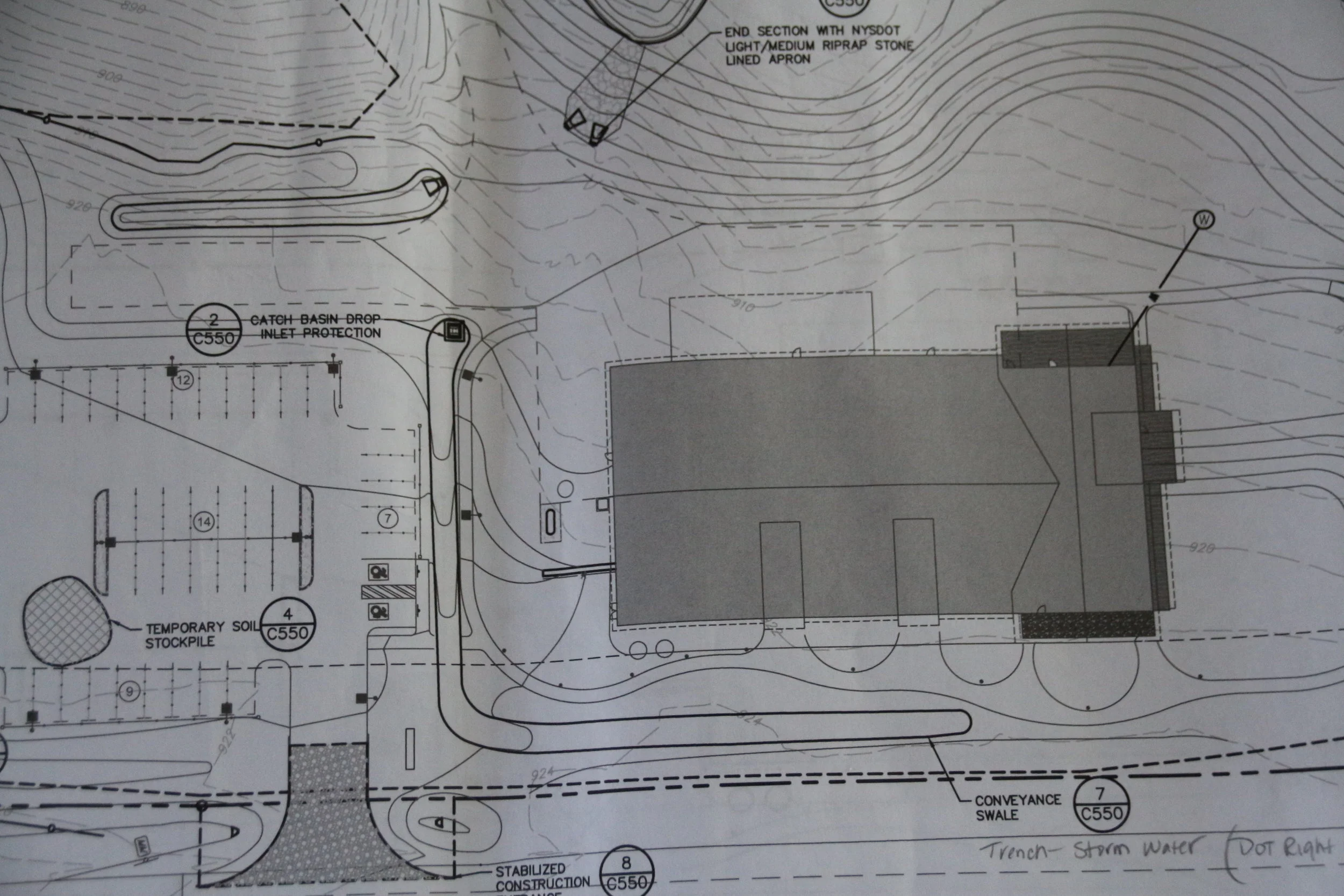

Paul points out the recently poured cement walls on the lower level, which will be for a huge brew house. (Engineering nerds take note: the foundation goes down six feet and has an 18-inch footing. The building is rated to withstand hurricane-force 120 mile per hour winds. Thank goodness, that’s not likely to ever happen, but then, there was this. (link to hurricane Irene)

The top level will feature the tasting room — with radiant heated floors — which opens on to a deck with spectacular northwest views of the high peaks.

“We hope to have our live music area here on this grassy area in front of the viewing deck. Folks will also be able to sit on the grass in front of the stage. Can you image hanging out here on a nice day with that view, with a bunch of dogs running around and playing Frisbee?”

Pointing to the left of the site looking towards Route 9, Paul imagines where a children’s playground might be.

“We will most likely build some outdoor restrooms to the north of the main building. Over here is going to be our handicapped accessible ramp which will be very close to handicapped reserved parking spaces”.

To the left will be grain silos close to the brewery and a parking area. A private road for deliveries will run from Route 9 to the back of the building.

Looking at the cement floor Paul shows me where the keg washing station will stand, where the delivery door will be, the tanks, fermenters, cool room and canning line, just to name a few of the big items.

Up close, you get an understanding of just how huge this enterprise will be. To appreciate just how big, consider these numbers: the Schroon facility and Paradox’s contracting business annually produce 3,500 barrels.

“Right now, with the tanks that we have on order we'll be able to produce about 18,000 barrels of beer. So, if we want to expand I could take my 40 barrel tanks, replace them with 120s, and now I'm up to like 25,000 barrels”.

But there’s more: “Well, the capacity for the brew house is actually 55,000!

(Help - I think I’m drowning in too many beer facts!)

The brew house comes from GEA Brewing in Germany. It’s so state of the art, many of the labor intensive tasks vanish. That will allow head brewer Devon Hamilton and his staff to spend more time brewing.

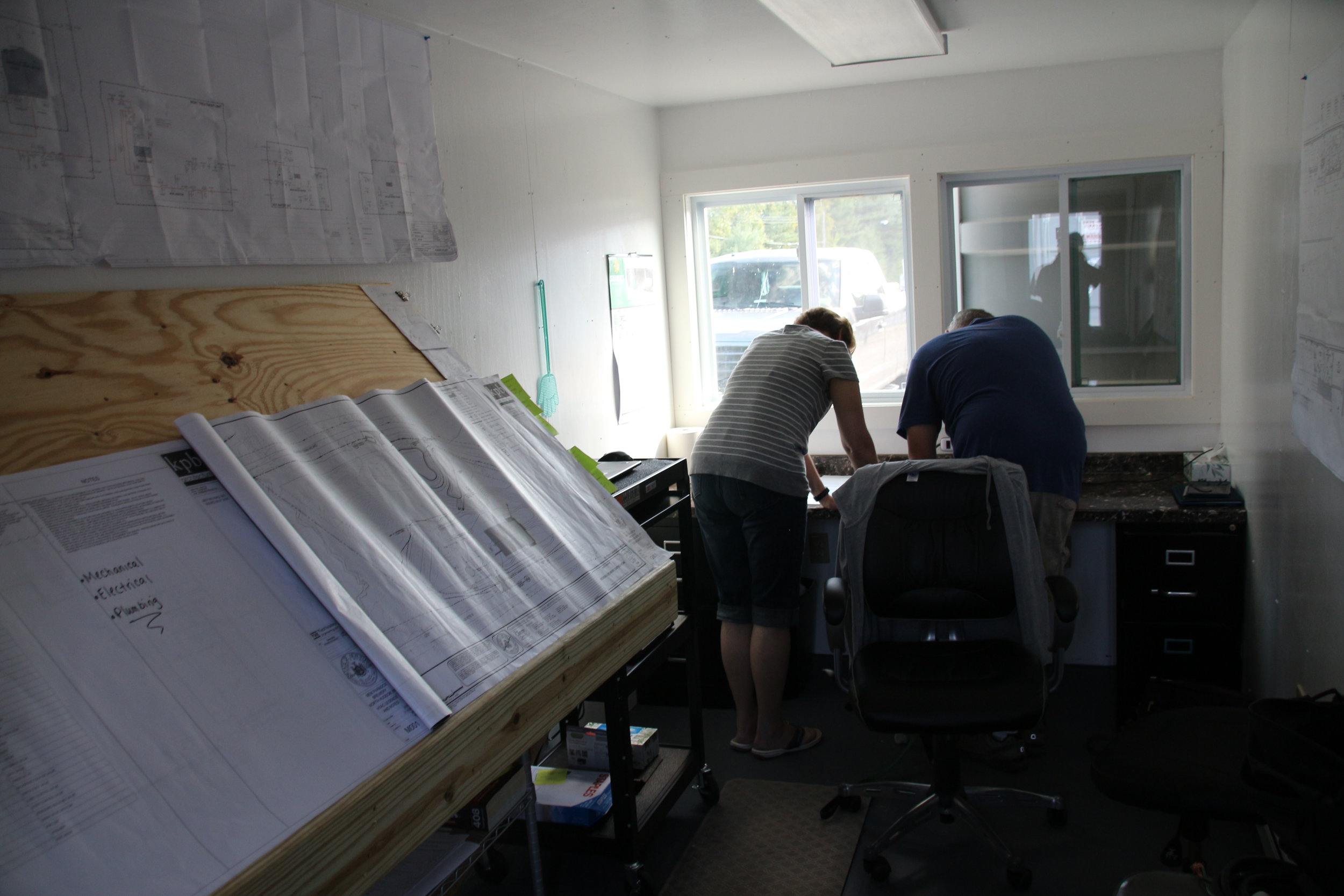

The brewery was designed by Keith Buff, “a friend of a friend.”

“This is his first brewery. Keith went out by himself some time ago and we are probably his largest project ever, and he is a great architect. He has done a great job. He’s on everything. This is all Keith's design. When we saw the design, we said, wow, we liked it right away”.

The final stop is to check in with the project manager Susan Carlson, the wife of GC Carl. We are in small air-conditioned office inside a shipping container.

They go over the schedule for the next few months. Paul needs to make sure the brewery’s siding is up before the shipment of the brewing equipment arrives from Germany.

Paul says what he knows about building a brewery qualifies him to be a consultant for others who share his dream.

“That's a learning curve, you know, like, starting a brewery, which was a learning curve, also”.

But for now Paul is focused on getting his brewery up and running.

“Do you have to pinch yourself sometimes?” I ask.

“Yeah, I really do. It's pretty remarkable. It's a lot of work. It’s going to be awesome.”

Paul as a home brewer.